Safely suspend heavyweight objects from ceiling structures with confidence.

A range of tested hanging brackets available in four loading options, up to 1000kg. Commonly used to suspend chandeliers, artwork, signage, and climate control equipment. Heavy duty tested hanging brackets from Penny Hydraulics are all individually proof load tested and marked with the rated load capacity.

Hanging bracket models:

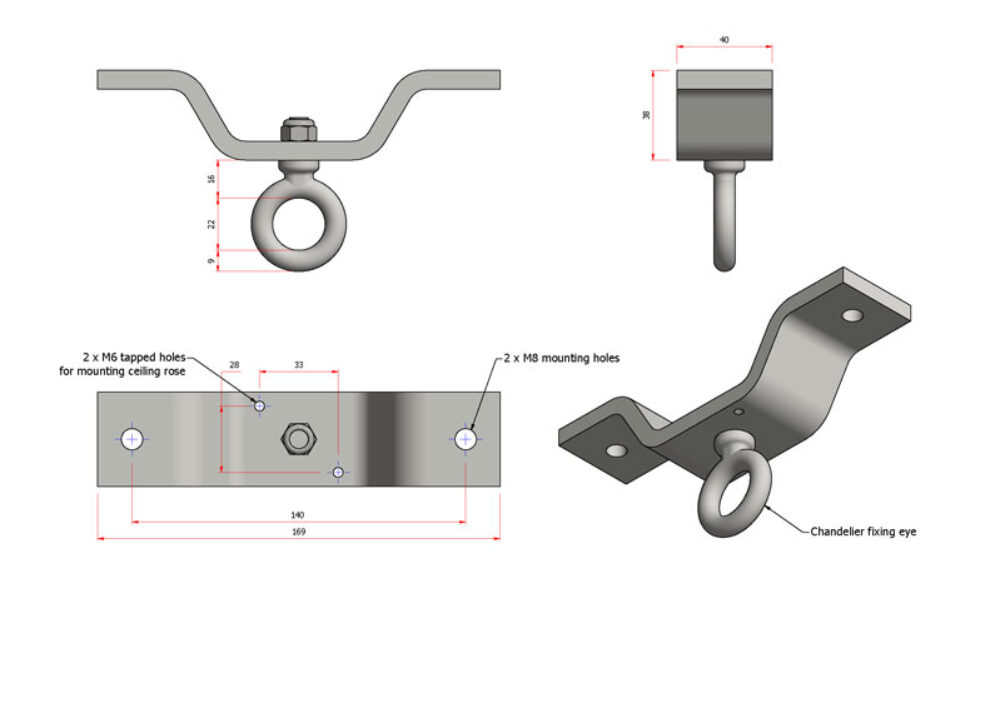

100kg maximum load – RLF-100

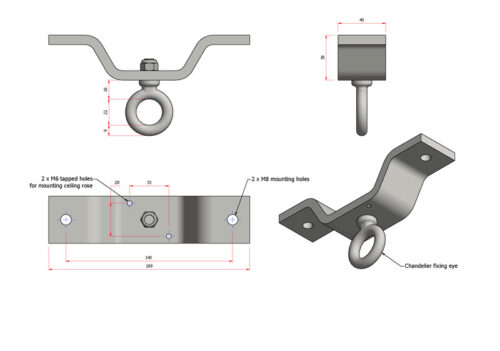

250kg maximum load – RLF-250

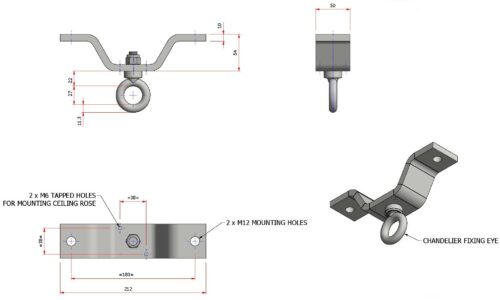

500kg maximum load – RLF-500

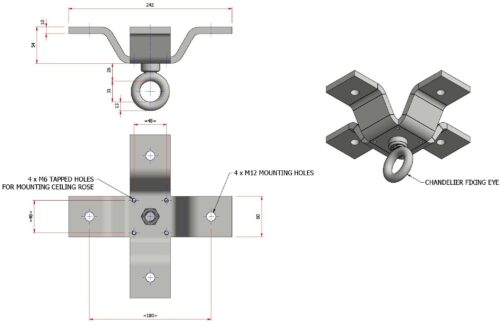

1000kg maximum load – RLF-1000

All hanging brackets are manufactured at our purpose-built UK factory, so we retain absolute control over quality and testing procedures. For peace of mind, we supply every anchor with a manufacturers test certificate, to comply with safety regulations.

When it comes to objects suspended at height, make light work of cleaning and maintenance with an electric lifting winch. Avoid the risks associated with working at height by lowering the suspend object to ground level. Not only is disruption minimised, but maintenance hours are dramatically reduced. Once the object is raised and in place, the electric lifting winch can be completely hidden, with no mechanisms visible.

Most commonly used for lighting and chandeliers, an electric lifting winch can also be used to access:

- Artwork

- Ceiling fans

- Speakers

- Banners

- CCTV

- Sensor units

- High mast fixtures

Read how to simplify maintenance with an electric lifting winch.